Services

Reverse engineering

Euro Stampi has the technical know-how to perform Reverse Engineering processes. They allow to analyse a product prototype in a detailed way and build a suitable mould efficiently and precisely.

We can perform such processes both on products and on moulds and mould parts, in case 3D data are not available.

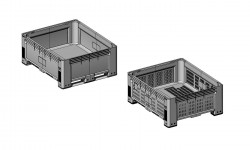

Product Design

We design products for the packaging, ecology and handling industry. We optimize shapes and engineering to create a product with the highest functionality, both in the use and in the production.

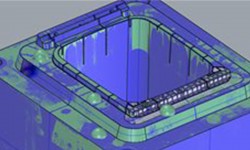

Mould Flow Analysis

For our design work we use simulation software to perform precise warpage and filling analysis. Together with our experience, this allows us to support our Customers in the choice of moulding materials for their products.

Mould Design and Manufacturing

Euro Stampi designs and manufactures in a safely and reliable way and is appreciated in Europe and outside Europe as one of the most experienced and reliable manufacturers of medium/large size injection moulds for thermoplastic materials.

In-House Trials

Euro Stampi provides for complete in-house mould trials. This speeds up the whole production process and guarantees the final quality, which is our trademark.

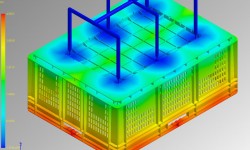

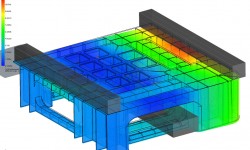

Static and Dynamic Loading Simulations

We perform in-house simulations to supply a final moulded product of highest quality. Through static and dynamic product simulations we guarantee an excellent reliability in the production.

Products testing area

At our company, you can run testing simulations in accordance with EN/AU/USA standards to gain more insights into your product already at the trial stage

3D Measuring

We use metrology software for precise measuring of dimensions and flatness, which is useful both for final check and product prototyping.

Mould Repairs and Modifications

Euro Stampi provides for technical assistance and repairs of moulds, even if produced by other mouldmakers. Furthermore we can modify your moulds to reach the highest efficiency necessary for your needs.

Custom moulding

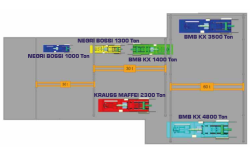

Thanks to our 6 injection machines ( Negri Bossi 1000T, Negri Bossi 1300T, BMB 1400T, Krauss Maffei 2300T, BMB 3500T, BMB 4800T) we are able to realize not only trials of our moulds, but also production and pre-series for medium and large sized parts.

K 2025!

Euro Stampi will be attending K 2025 (International Trade Fair for Plastics and Rubber) from 8 to 15 October in Düsseldorf, Germany.

We will be delighted to welcome you at Hall 1 – Stand C86, where you can discover our solutions and share your projects with us.

Take the opportunity to meet us in person and create new opportunities together!

Contact us to schedule a personalized appointment.

IMSA MF 1500 BB

Continuous investment in new machinery for higher manufacturing efficiency.

This time we got a new Drilling machine: IMSA MF 1500 BB!!

Score ECOVADIS

Euro Stampi is pleased to inform all its customers and suppliers that our company has recently achieved a score of 52 from Ecovadis, a company specializing in corporate sustainability assessments.

This result confirms our ongoing commitment to responsible, transparent practices that respect both the environment and society.

We will continue to work with determination to further improve our ESG (Environmental, Social, and Governance) performance, fully aware of the importance of a sustainable approach for everyone's future.

Thanks to all who contributed to this achievement.

BMB 3500T

Continuous investment in new machinery for higher efficiency.

This time we got a new BMB 3500Ton, available to test your new moulds!!